| |

@As mentioned earlier, we have a long history of designing and producing

CIP rubber molds. Our |

| recent arrive at the conclusion that to effectively cope with the various CIP process issues that our |

| |

customers are facing, including high running cost, deformation and compound

density/filling density |

| |

variations, it is necessary to work on a much wider range of operational

factors beyond such rubber |

| |

molds, as material temperature control and mold filling parameters. |

| |

here are other urgent issues involving the CIP industry that are getting

greater in recent years, the |

| |

most critical ones being the need for better working environment in the

workshop including airborne |

| |

particle control, which is driven by regulatory pressure such as the tightening

and more vigorous |

| |

enforcement of Labor Standards Act, and the same for further manpower saving

due to economic |

| |

slowdown triggered by factors such as high yen appreciation. |

| |

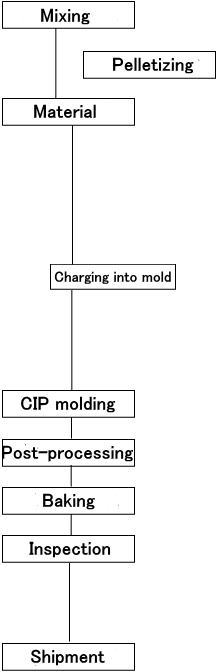

To offer a one-stop solution for all of the above issues, we offer a complete set of design, fabrication |

| |

and installation services of CIP material handling systems from material

mixing to product shipment |

| |

with the aim of contributing to productivity improvement, manpower saving

and better quality control |

| |

for our customers.

|

| |

The system described below is just an example. We are ready to discuss your requirements in depth |

| |

so as to offer the most effective CIP peripheral solution to satisfy your

needs. |

| |

|

| |

|

|

| |

| |

| To minimize material deterioration that can occur due to temperature fluctuation after the CIP |

| material is mixing or pelletized until it is charged into the rubber mold, each different type of |

| prepared material is kept in a separate storage bin located in an air-conditioned area, which is |

| partitioned into sections by plastic curtains to help assure better material

segregation and also |

enhance airborne particle control inside the plant.

|

| An automatic material feeding system into the storage bin is optionally available (a dedicated pit |

is required).

|

| An automated calculation container fitted underneath each storage bin

allows drawing the |

required amount of material for each production. A dust collector installed

in the area

|

| prevents particles from getting airborne while the material is drawn from

the bin. |

|

| |

| Material drawn from the storage bin passes through the automated calculation

container and is |

| then handled by an auto crane system to be carried to the area above the rammer, which |

charges the material into the rubber mold.

|

| After temporarily placed on a table, the material is run through a screw

feeder or other feeding |

mechanism and finally into the rubber mold.

|

| Once inside the mold, the material is thoroughly and uniformly crushed

and compacted by the |

| rammer to achieve the best filling density for CIP molding. |

| |

| |

| |

| |

| |

| |

| An automatic measurement and inspection system checks the size, shape and

other properties of |

| the finished product before it is shipped to the customer. |

| The system employs various measurement techniques to check various inspection

items. |

| |

| |

| |

| |

| |

@@ |